Cabs

Second Generation Build

The First Generation Cabs were horribly oversized (add photo for evidence) and after building a laser cut

MoPac Drovers Caboose kit, I decided to try my hand at building the cab using laser cut 1/64" aircraft plywood.

Plans and Parts

Assembly steps:

1. Laminate 1/64" pieces.

2. Prime and paint opposite sides: wisconsin central maroon, dark green, and metallic gold

3. Add window material on inside of sides and front

4. Add Details to outside of sides

4. Assembly: Sides to Front

5. Add Top

6. Add Bottom

7. Add Back

8. Add Boxes

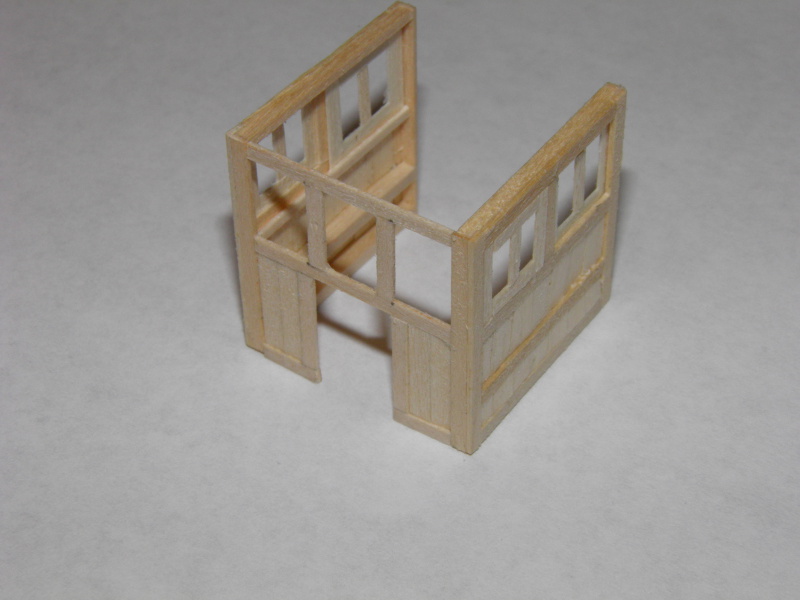

First Generation Build

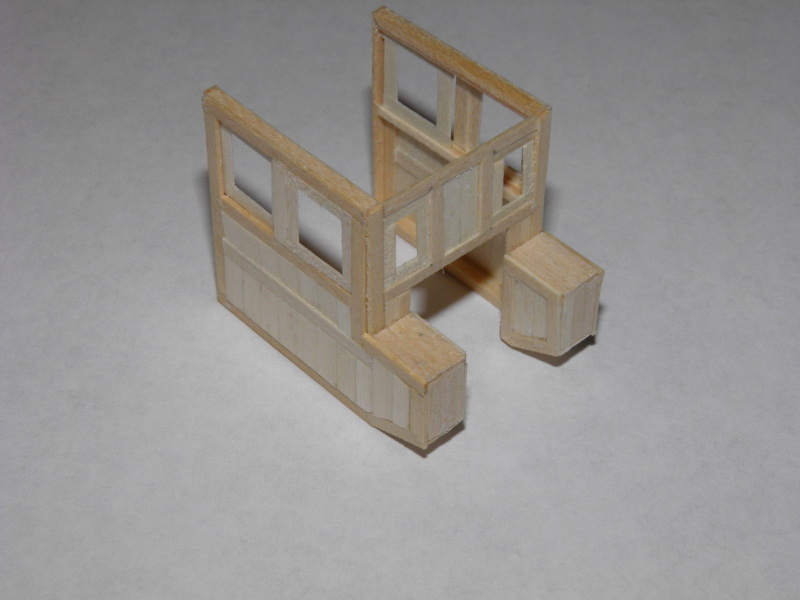

The first attempt to build the cabs used scale lumber and rail and style construction...

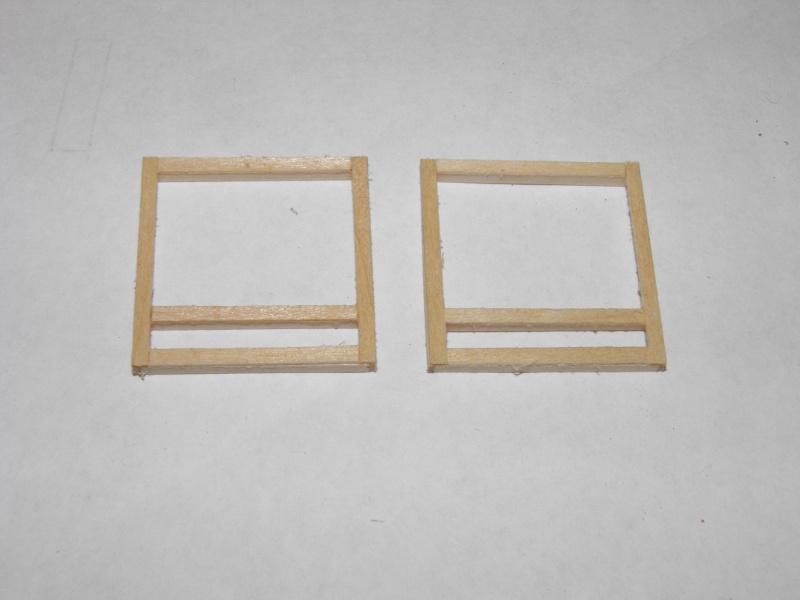

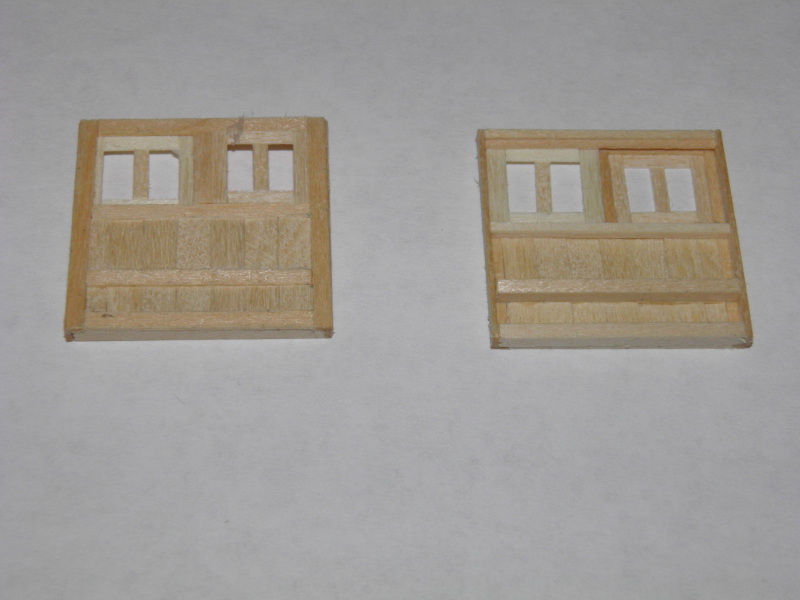

| The first step in building a cab side is to lay out the rails and styles using 2"x6" with 6"x6" for

internal supports. The exception is the top support, which is 4"x6" (to leave clearance space for the operational

window panel). For the six wheeler cab, a piece of 2"x8" is used for the lower middle rail. |

|

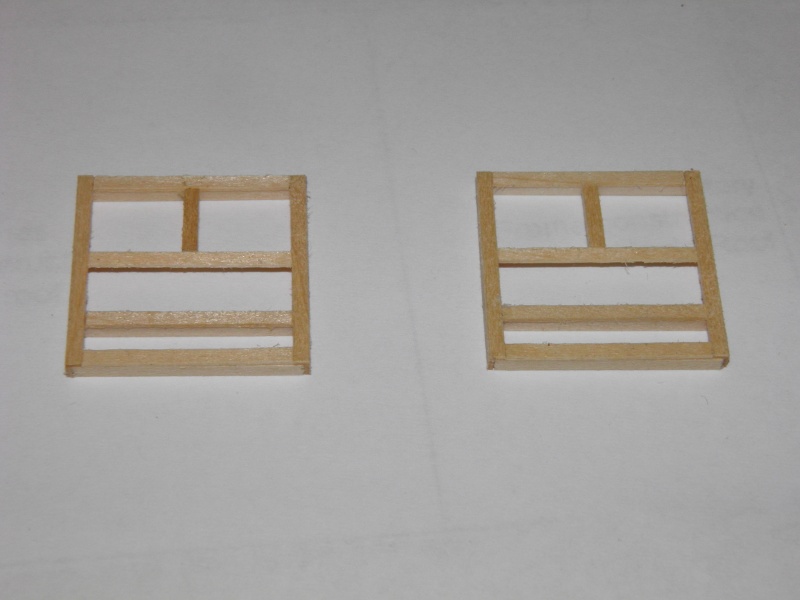

| The panels and window openings are framed in using 2"x6" (a vertical 2"x8" is used for the six wheeler cab). |

|

| The wooden panels are constructed from 1"x12" edge glued into the available openings. |

|

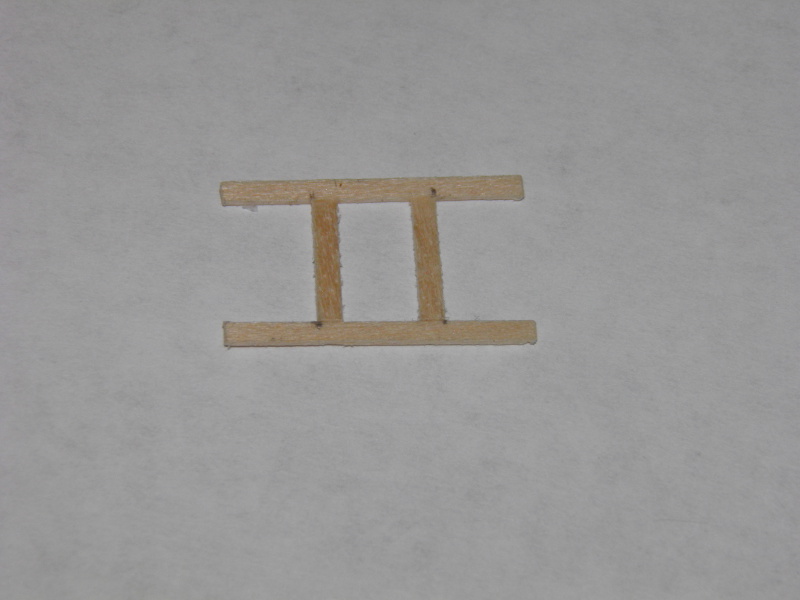

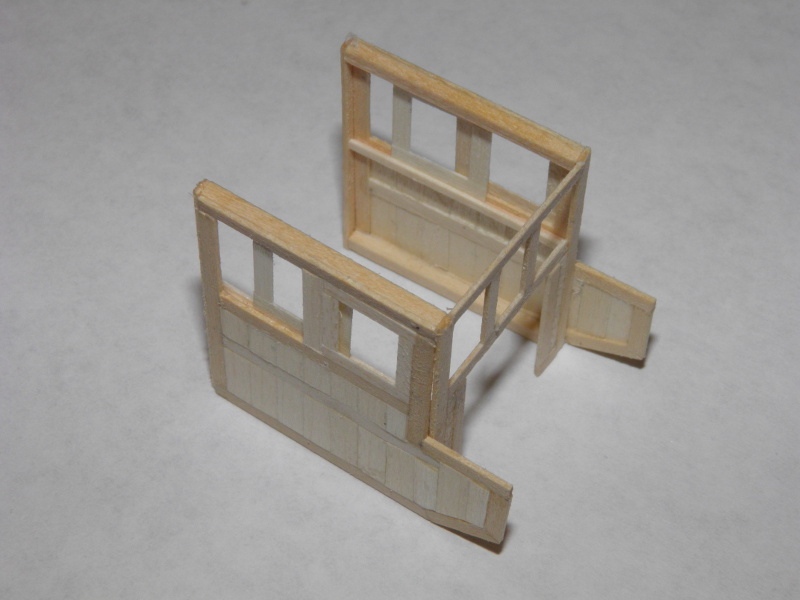

| The fixed window panel is built into the front opening using 1"x6" again modeling rail and style construction. The moving

window panel is built using 1"x8" for the outside rails and styles and 1"x6" for the divider. It is then placed over the back

opening and framed in at the top with a piece of 2"x2" and at the bottom with a piece of 2"x2" and a piece of 2"x4" to form the

channel the window moves in. |

|

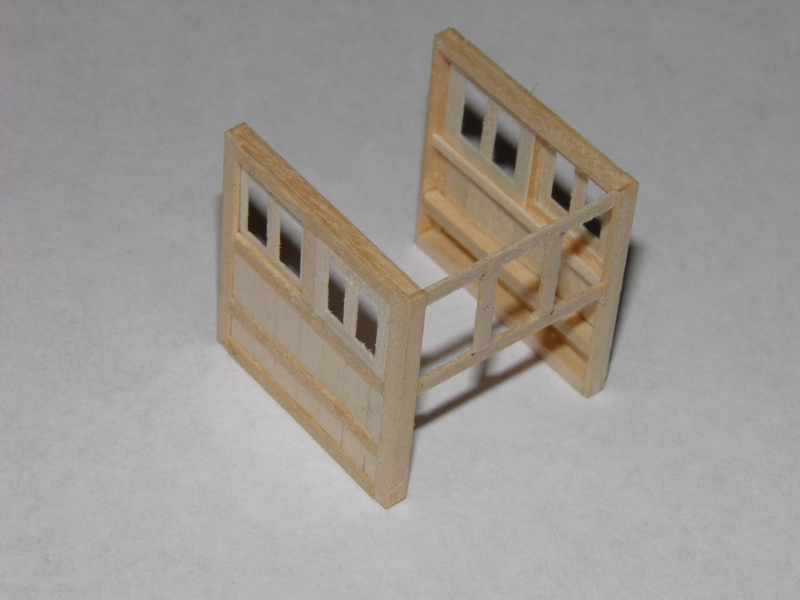

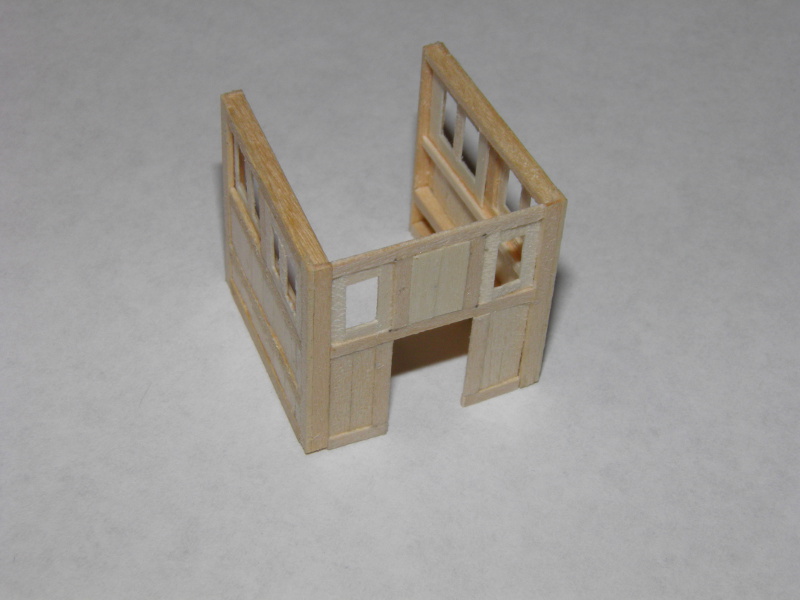

| For the front panel, the first step is to cut and assemble the full length 2"x6" cross pieces and the 2"x6" spacers |

|

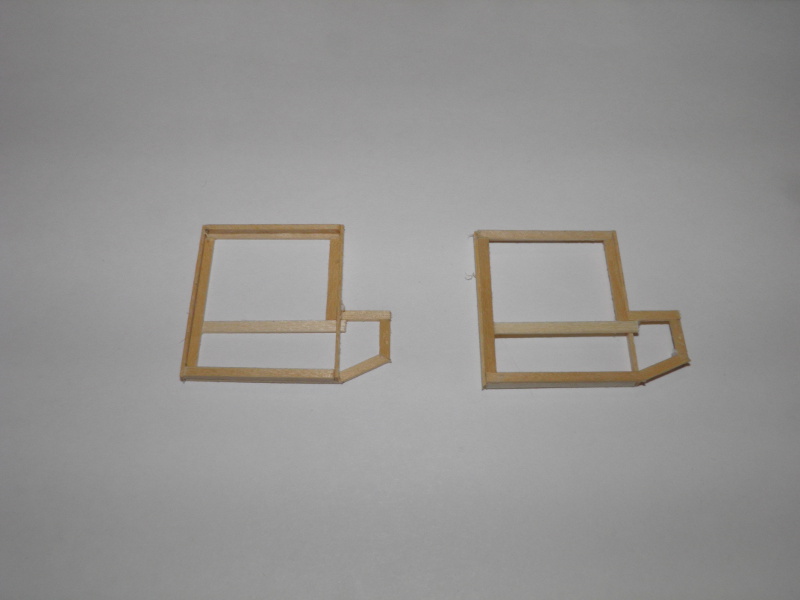

| Now, the two side panels can be glued to the front panel assembly to begin forming the front of the cab. |

|

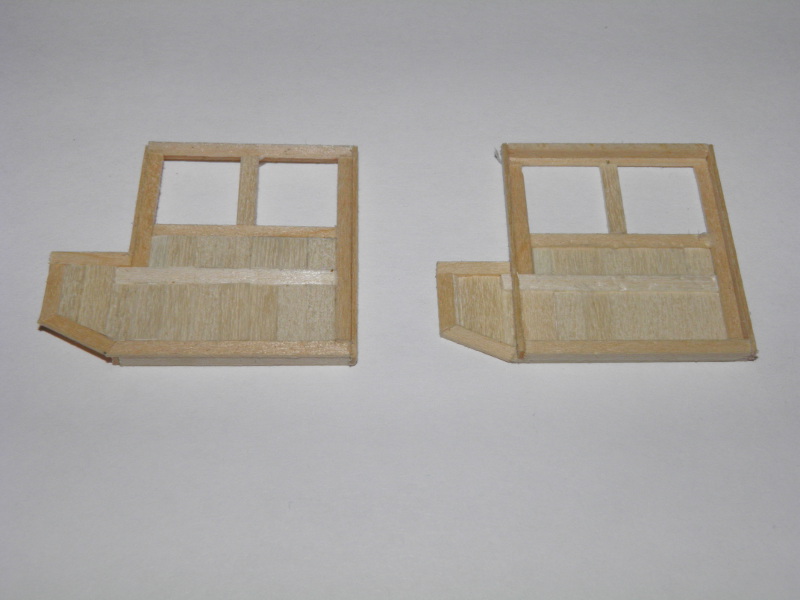

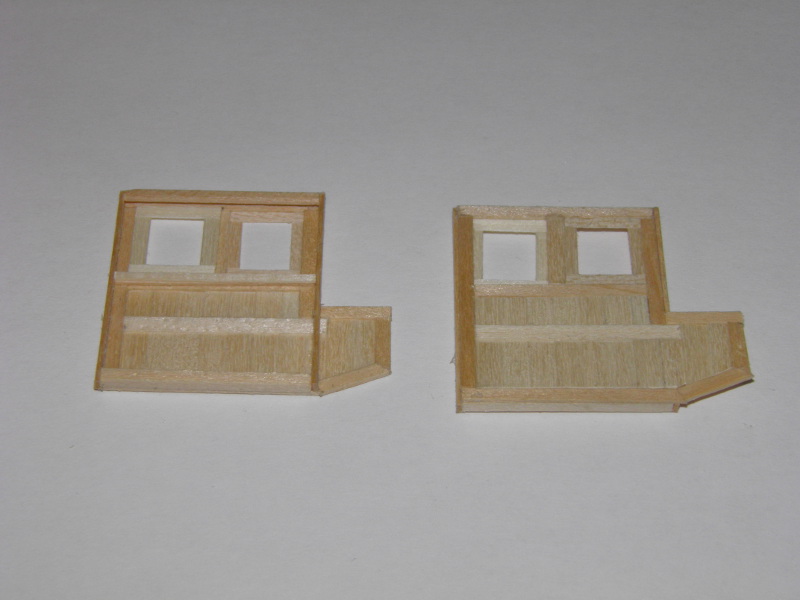

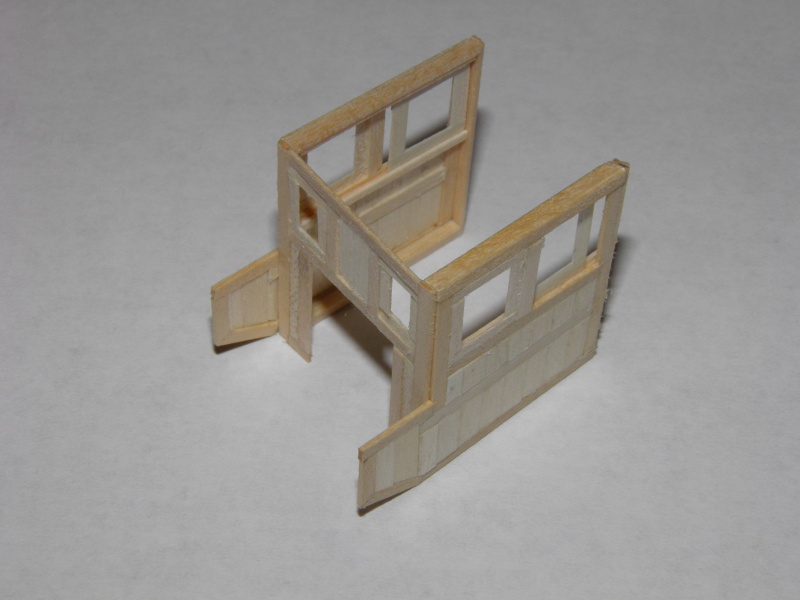

| The drop panels are constructed of 2"x6" and appropriate 1"x material - for the four wheeler cab, two 1"x8" pieces

are used and for the six wheeler cab, a single piece of 1"x6" is used. |

|

| The upper panel can be filled in with two 1"x10" pieces for the six wheeler and two 1"x12" pieces for the four wheeler

and the window openings framed in with 1"x6". |

|

| Finally, the six wheeler cab gets the two lower extensions that surround the boiler built up from 2"x6" and 1"x10" pieces |

|