| Navigation: | Home | Blogs | 2013 Posts |

|

Posts from 2013 |

More fun from the Kimber Mill:

More work on the Kimber Mill over the last two weeks:

Based on input from folks that worked in a stamp mill, the rollers and pan of the Chilean mill would be covered in mud, so the body gets dyed with brown India Ink.

Built the bent for the flume with 1/8" dowels and 2"x6" boards.

Add the bent to the flume along with two 8"x10" stringers.

Open the roof rafters for the flume and add head rafters.

Added NBWs where the wheel spokes meet the outside walls

Work deadlines have thrown a real spanner into my modeling time over the last four weeks. All I have that is worth a photograph is the finished floor of the Kimber Mill.

Since I was at MinnRail last weekend, I've left the update to this week, and the only real update is that the rafters for the roof of the Kimber Mill are finished:

I needed to update photographs on all the various jigs I now have:

I had forgotten that I should add some links on my Turnouts page. Basically, I've put in the cross links to the wiring page for how the turnouts are wired and to the layout page for how they are mechanically thrown.

On the Kimber Mill, I finished up the casement windows and casement doors, and have cut and fit enough of the roof rafters to add purlin posts and braces, and assemble part of the rafter structure.

For the waterwheel, I designed a stone pillar and had two of them printed at shapeways from sandstone. The waterwheel is mounted with 1/16" brass axle and mounted the axle to the stone pillars using pillow blocks from Crow River Products.

Lastly, I marked out the places in the upper floor platform where the maintimbers pass through, drilled and filed them out. The floor is then mounted to 12"x12" and 8"x12" pieces stacked to provide 32" of height to provide slope for the mill work and the main timber structure inserted into it

I realized when going back through the Operational Considerations that I needed another 36 buckets. So, I cut them out, stained them and added them to the water wheel along In addition, I've added a 3/32" metal axle and weathered the metal parts with primer and grimy black.

I finished adding nail marks and water staining to the upper floor platform on 24 inch centers

I realized that the collars for the Chilean Mills would be better made from copper tubing, rather than trying to 3D print them (they are just too small and thin otherwise). So, I cut length from 3/32" copper tubing and center drilled with a #53 bit. Here are the collected parts, the assembly and the result of weathering.

Since I've had the last week off (with kids - my wife was in Atlanta, so no NNGC for me this year), I decided to work on the layout a bit:

Or, how much redesign work is possible *without* a photograph...

Last month's B&CC update led to a cessation of building efforts and a revisiting of the design of the Kimber Mill. For those who aren't familiar, I introduced it as a

"model is based on the description of the Kimber Mill provided on pp 101-102 of _The Gold Mines of Gilpin County, Colorado_. While there are no pictures of the mill available from the time period, the following points can be determined:

One individual who read this description (and who has an interest in the history of mining development) reached out to me privately and began researching this mill. His contention was that this was actually the Polar Star Mill operating under a different name. Initially I disagreed, but as I uncovered more scraps of information, I’m now in some agreement with him. Together, we’ve pieced together a history of the mill from 1868 up through the early 1900s.

One of the big challenges is that Job Kimber appears to have been a bit of a wheeler/dealer and had interests in many different mills in the Colorado area. He was operating the one I’m looking to build in 1871 along with Garrott and Buffington. To further confuse the design, the mill appears to have first been constructed in 1867, an addition added in 1868, and then a further addition added in 1870. So, it should end up being in three pieces, rather than a block structure (as I was previously designing). On top of this, we uncovered that the stone building was erected in 1875 “over the old frame which was removed“, which indicated that the outer building should be wood construction rather than stone.

At this point, more digging in the DPL turned up the following two photographs:

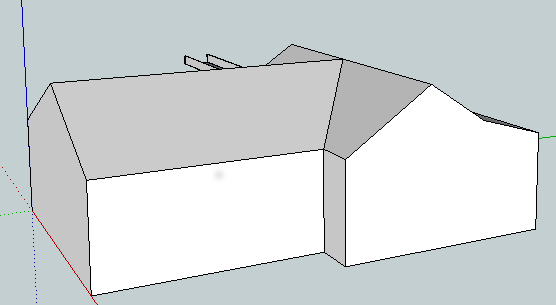

Most definitively a wooden frame, likely with a shingle roof, and certainly looking like a structure that had been built in three pieces. So, I’ve pretty much torn up the old design and started on a new one, using Sketchup to help me visualize how the floor plan and perspectives would look in three dimensions. The result is the following 3D perspective:

and a new set of (still incomplete) plans.

I figure I have another two weeks for doing design and then I’m going to start (re)building the last week of August. The flume in the plans is a really tempting place to start out.

So, I’ve updated my Kimber Mill build page to remove the parts (like the Ore Bins, Windows, and Terracing) that aren’t part of the current design. On well.

Lastly, for those modeling in and around Colorado, I’ll suggest the following web sites – some (like the DPL) are well known, some others might be a resource people aren’t as familiar with:

Repaired the truck on one of my two passenger combines - thanks to all the folks that suggested ideas to another poster that helped me figure out the best way to solve my problem!

On the Kimber Mill, there's been a lot of design work for the building as a whole and I've turned that into a set of subfloor terracing to get the right slope for the amalgamating tables. The current side/cutaway view is no longer available as a PDF and the photo of the assembled subflooring has been removed.

I think the next portion of the build will be the outflow ramps from the Chilean mill bases to the lower amalgamating table and the waste trough running from the lower tables to the wall of the mill.

Wandered off to the TLR NMRA convention in Minneapolis in May and the engines were well received. For those AP-type wonks, all six received merit awards and so I'm due a Motive Power certificate in the future, leaving only Prototype, Scenery and Association Official remaining to chase. Sat through a clinic by Jon Addison and got a lot of good ideas for modeling techniques, including one that I'm going to try and use to make the outside stone walls of the Kimber Mill. If it works, I'll reuse it for the Blackhawk station.

The end of May and beginning of June was our local bi-annual operating session, and though the B&CC wasn't operating, I did help out with a friend's layout.

Took engine #6 and car #201 down to the MCoR NMRA region last weekend and realized two things: First, I really need to repaint the engines (the color needs to be darker) and second, I have to take a pin-vise and drill bit and open up the pin holes in all of my link pockets before I attempt operations. The pins don't want to fit in the holes and through the drawbars without it. The jury is still out on weathering the drawbars and pins - part of me says "do it" and part of me says "leave them a color that can be found on the layout".

While at the MCoR convention, I got to sit down with Ron Morse and found out the that Sundance books on the Colorado Central and Gilpin Tram were worth my while. Lo and behold, a dealer at the convention had a copy of both of them and Ron was right- Anybody modeling the Clear Creek area should invest the money in these books.

Back home, I've got two engines apart on the work bench - it's time to see how much more weight/lubrication they need to make them run well enough to make me happy (more as we go). While work has been crazy, I have the itchy palms to get back to work on the Kimber Mill and so I've been doing research again. Many thanks to all those who answered my questions on building techniques. I was able to run down several sources on Google Books from the mid to late 19th century and I've got most of the outside building designed now. Still need to add the dormers, flesh out the windows in the gable end walls, and finish the north and south side walls and I can start working on jigs for the windows and roof and start the wall construction process.

Unfortunately, I managed to drop one of my engines while working on the brake gear and the front end mounting plate didn't survive the fall. The good news is that I had a bunch of free time while "sitting" the contest table at our local NMRA division's show the following weekend, so I used that time to repair the engine and give an informal clinic to passers-by about both it and the models people entered for merit award evaluation.

The cast steam domes I was going to use for the six wheelers didn't fit, and I decided I didn't like any of the cast whistles, so I designed custom ones of each. Here's the photo of the domes and whistle for the four wheeler and the photo for the six wheeler showing both the steam dome and the whistle.

As promised, here is a four wheeler with the brake installed as well as with the rest of the valve gear added. Of course, the six-wheelers also got brakes and valve-gear.

Next step was to paint the cabs and glass the windows on both the 0-4-0T and 0-6-0T. After which, the bells, domes, and whistles are added (sample four wheeler and six wheeler). Cab detailing is made up of strips of 2"x2" cut to shape and painted gold before added. On the 0-4-0T it's pretty simple, while the 0-6-0T has a bit fancier detailing.

Lastly, eyelets and .018" wire made up the hand rails above the running boards, more .018" wire is added as the bell pull and the six wheelers get pieces of flat brass added to model the water tank hatch (I just flat ran out of room on the four wheelers). And so, after 35 months, two restarts, countless redesigns, may I present the Blackhawk and Central City motive power fleet:

The build is definitely getting closer to being finished. I can't say it's in the home stretch yet, but I think I'm in the final turn...

Added more details: piping from the cylinders to the tank/boiler front is modeled with 0.022" wire on both the Four Wheeler and Six Wheeler.

For the cab, the rear coupler pocket is mounted to a scale 12"x18" cross member glued to the cab subfloor. Got my hands on some 1/16" sheet lead for weight, so each cab now has a square inch of it under the scale 2"x12" edge glued cab floor (Here are the pictures of the 0-4-0T and the 0-6-0T at this stage). While some of you might have heard that I was thinking of staining the cab, this idea just DID NOT work (luckily I tried it on some scrap wood I had before getting myself into a world of hurt), so I fell back to painting the inside of the cabs with Pullman Green (going for a preservative green darkened by the wood creosote look). For the four wheelers, the backheads (from PSC) are glued to 1/8" long pieces of 1/2" diameter plastic tube and the whole backhead assembly given a coat of Tru-color's grimy black (but not too heavy) and then glued in place on the front wall of the cab. The six wheelers required an additional piece of 1/32" plywood to be cut and shaped to fit the gap around the boiler cover. The roof of the cab is 6"x6" edge glued timber covered by 1"x12" edge glued lumber running in the transverse direction (the inside is painted before it's glued in place). Here's one of the four wheelers and one of the six wheelers waiting for their cabs to get a coat of paint and final detailing.

I've started work on the brake assemblies (1/2" plastic tube cut 1/8" in length, then in half and mounted to 60 mil rectangular bar plastic). My original design (for two and three wheels turned out to not quite fit, so I made some adjustments and will have pictures next update.

The package from Shapeways arrived - in it were half the parts need for the Chilean mills that will be part of the Kimber Mill build. Why half do you say? Because I slipped a factor of two when I ordered (well, better that than going the other way). Here's what one set looks like. Also in the package was an experiment with a pair of jigs for laying out 2"x4"s on 24 inch centers (filled in and resulting sample) as well as 16 inch centers (filled in and resulting sample). I've redone them to (1) make the notches a little wider (anybody else notice that 2" scale lumber isn't really scale 2"?), (2) and a little deeper (a 3" deep notch will make it easier to hold the studs), as well as (3) make the jig large enough to hold a 10' long wall section, and lastly (4) add a jig for 18 inch centers and then I think I've got something for future walls. Yeah, I know, it's waaaaaaaaaaaayyyyyyyyyyyy over the top but (shameless plug) you can order them from Shapewaysif you want to join me in my geekiness.

Now back to the ongoing engine build.

I finished wiring the headlights (four wheeler and six wheeler) and have also reassembled and tested them, and yes they run! The decoders need to be programmed (still address 3, and need to flip the bit to compensate for the reversing gear) and will need some weight, but here is the four wheeler and six wheeler when put back together.

The next step was to finish painting the tanks and fit them. So, I pulled out the Model Master Metallic Gold and went dry brush happy on the gilding and lettering. To bring people up to date on the tanks (I haven't talked about them in a while), here are a couple of images/photos. First are screenshots of the four wheeler tank design and six wheeler tank designfrom Sketchup (I decided to raise the gilding and lettering 1/64" so that I could use the dry brush technique for painting). Next, I had the tanks made at Shapeways out of their Frosted Detail and Ultra Frosted Detail Material and here's what a pair of them looked like when I got them. The tanks were painted Wisconsin Central Maroon and once I finished up the gold dry brushing today, here's what the four wheel and six wheel tanks look like. Lastly, here's how the four wheeler and the six wheeler look with the tanks fitted (yes I know the one isn't level - I'm planning on working on that)

In addition, I've also added the 6"x6" subfloors to the cabs and fitted them to the back of the frames and tanks, along with necessary shims so that the cabs are plumb and level (yes, I'm a geek) and now that is done, next will be mounting them from the bottom with some small brass screws and then adding a pair of 12"x12" runners to help hide the brass screw heads as well as adding the 12"x12" backing pieces that will support the rear coupler pocket. Here's two sample photos of the cab fits: 0-4-0T and 0-6-0T. At this point, I've also changed my mind about painting the cabs - I'm realizing now that if they were Wisconsin Central Maroon as well, the effect would be overkill, so I'm thinking of going back a few years earlier in time and staining them to model a natural wood finish before adding the gold trim.

It's time for another update from the B&CC. I'm still juggling my schedule to find consistent blocks of modeling time, so there isn't much in the way of new photos (or progress). On top of that, I may not be around in the next week or two as my grandfather passed away yesterday (he was the railroad fan that first got me interested in model railroading to begin with and in the Clear Creek as a specific focus) and I don't know whether there I will be flying to a funeral or planning a trip in June to my family reunion for a memorial service.

What I do have is another six wheeler cab picture with the front boxes finished and a couple more wiring pictures:

I'm hoping to get the headlight wired in this weekend and everything reassembled so that I can fit the cab floors and front metal plates next. I also have hopes that I will have more stuff soon as I did finally order the 3D parts for making the Chilean mills that the Kimber Mill used - they should be here next week, and I'll take some time to put them together.

Happy new year from the Blackhawk & Central City. The non-modeling news here is that I've left the lands of the semi-retired and taken on a new job. Good for the bank account, but I'm still juggling my schedule to find consistent blocks of modeling time. So, until I manage that, I expect these updates will be a little less regular than they've been in the past.

Anyway, in the last four weeks I've been working mostly on my engine build, specifically cabs, wiring and some paint and assembly.

I finally came up with a workable drawing for the six wheeler cab sides and here are pictures from the build. As with the four wheeler cab sides, one of the window frames is operational and slides from front to back:

I've worked up designs for the cab fronts and I hope to do some fabrication over the upcoming weekend.

For wiring and decoders, I'm on my third generation of decoders (I got tired of frying the CT ones with sound that I started with and my second attempt with Digitrax Z scale decoders worked, but they are still too large for the engines), TCS Z2 decoders: Here's an example of one "out of the box".

I trimmed the decoder wires to 1/2" length, and then stripped around 1/16" at the end, soldered it to the 6-pin custom connectors I got from TCS (see the engine build page for more details) and insulated with 1/4" of heat shrink tubing. Here is what you end up with and yes, that ruler shows it's less than 1.5" end to end. I'm currently working on the other side of the connectors and will add pictures as that gets done.

Since these engines are wood-burners, they get to be nice bright colors. So, I've been hand painting the detail parts before I do final assembly. Before that, I mounted the whistles in the steam domes for the six wheelers, and then painted up all the bells, whistles, and domes. I'm using: